Reshaping the Core of Battery Connections,

Driving the Future of Energy Storage

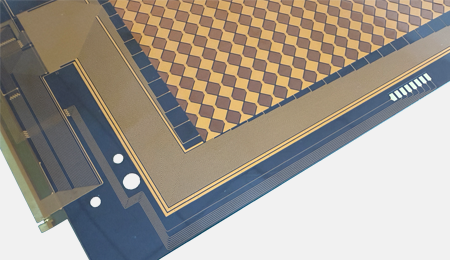

As the core of the CCS, our FPCs—lightweight, flexible, and highly integrated—serve as a reliable and efficient “nervous system” for battery modules.

-

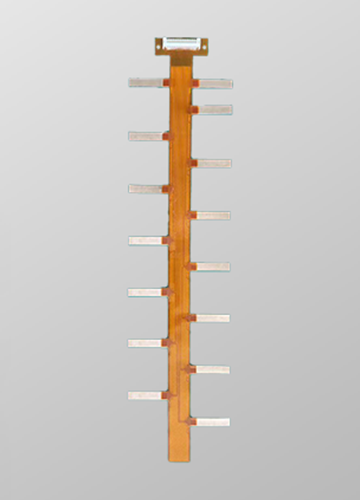

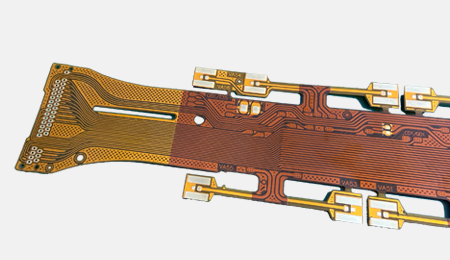

Custom FPCB for Electric Motorcycle Battery Pack

-

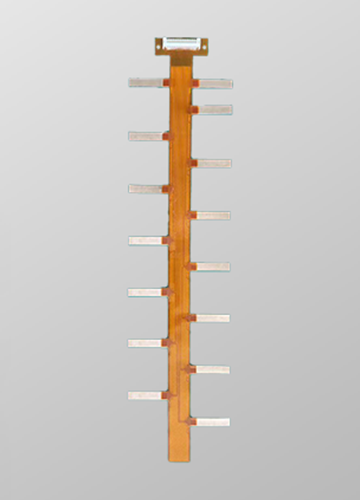

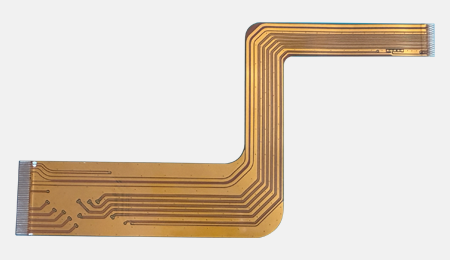

Custom FPCB for Electric Bicycle Battery Pack

-

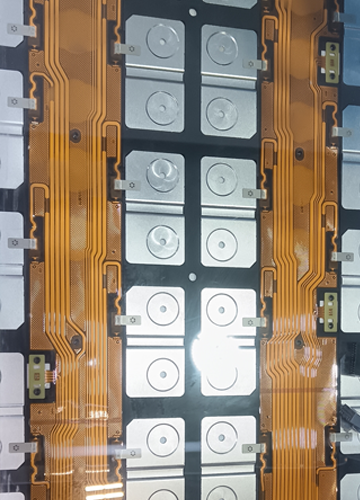

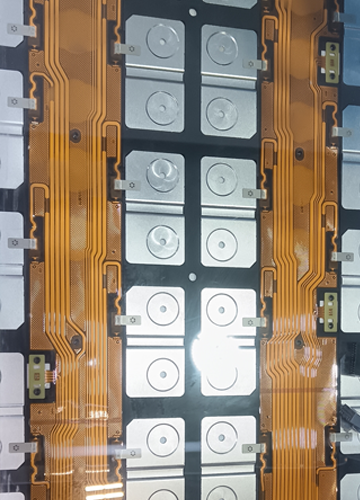

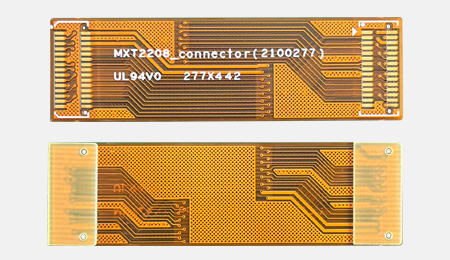

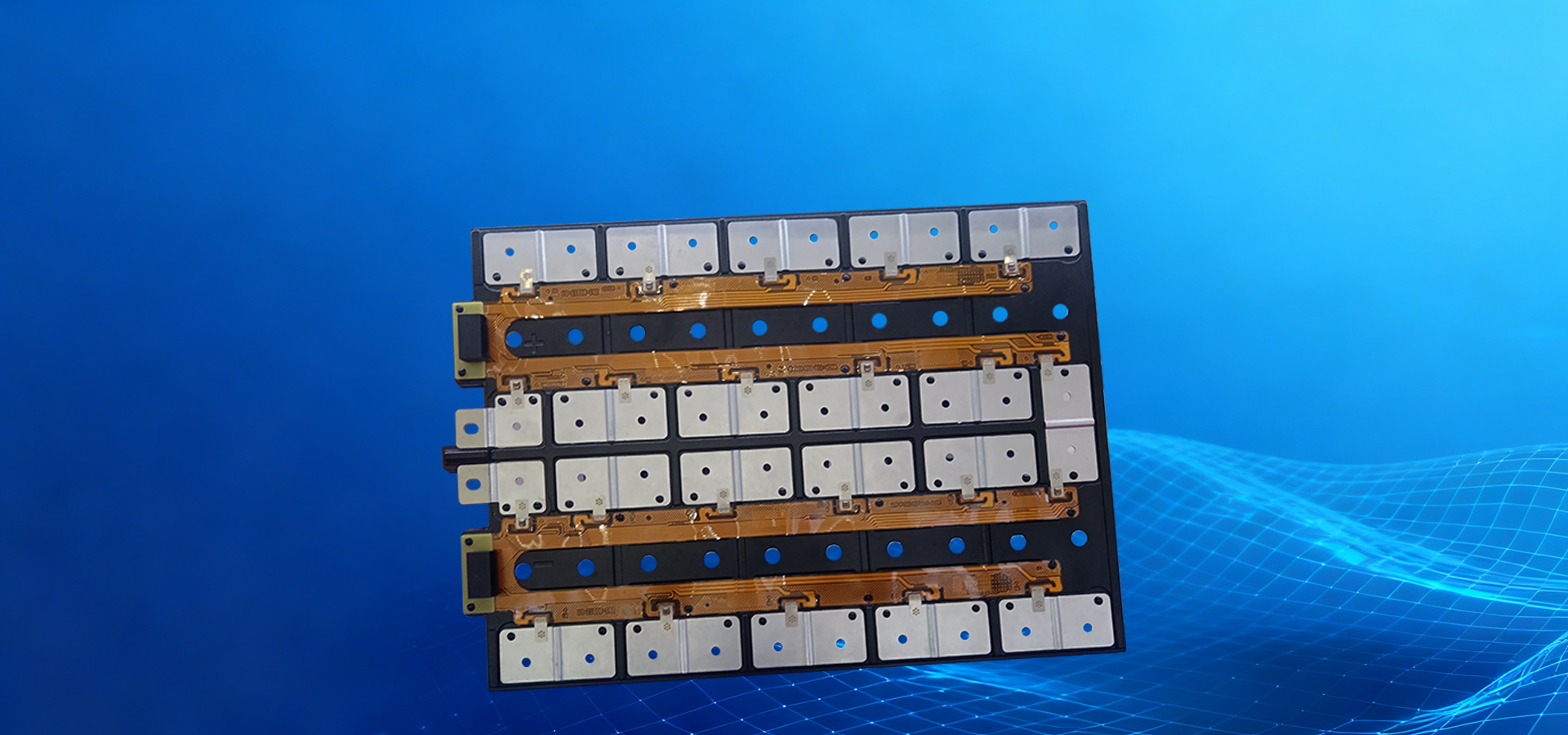

Custom CCS FPCB

By highly integrating sampling circuits, NTC temperature sensors, fuses, nickel strips, connectors, and more, FPCBs significantly save space. At the same time, they simplify battery pack assembly, enabling plug-and-play functionality. FPCBs are no longer just “wires”—they serve as an intelligent platform with sensing and protection capabilities, providing a precise and reliable data foundation for BMS.

Supports High Integration, Modularization, and Intelligence

Achieving Extreme Space Optimization and Lightweight Design

Compared with bulky traditional wiring harnesses, FPCBs are lighter and thinner, significantly freeing up internal space and reducing the overall weight of battery packs. Their flexibility also enables efficient routing within compact battery pack layouts, making FPCBs a key enabler for batteries that are smaller, lighter, and more powerful.

The use of FPCs enables standardized and automated batch production that integrates seamlessly into modern battery production lines. This significantly improves manufacturing efficiency and yield rates, making FPCs especially well suited for large-scale production of electric vehicle and motorcycle battery packs, and serving as a key driver for the industry’s scalable growth.

The flat structure of FPCBs provides a higher surface-area-to-volume ratio, enabling more uniform heat distribution and efficient heat dissipation while preventing localized overheating. In addition, FPCB materials—such as polyimide—typically offer flame-retardant properties, further enhancing the overall safety level of battery packs.

Optimized Thermal Management and Enhanced Safety

Improving Production Automation and Mass Manufacturing Efficiency

Enhanced Electrical Connection Reliability

FPCBs form circuits in a single etching process, eliminating hundreds of connectors and crimp points found in traditional wiring harnesses. This fundamentally reduces the risk of poor contacts, short circuits, and corrosion. In addition, the fixed routing of FPCBs prevents wear and loosening commonly associated with conventional harnesses, ensuring long-term stable and reliable signal acquisition for BMS systems.

High level of integration

Lighter weight

Thinner profile

Space-saving design

High degree of production automation

Clean and neat appearance

FPCB Solution

Rigid PCB Solution

Advantages:

· Shares some of the benefits of flexible PCBs

· Provides a certain level of structural strength

Disadvantages:

· Thermal expansion mismatch issues

· Differences in expansion coefficients compared to battery cells under temperature variations may lead to reliability challenges

Wiring Harness Solution

Advantages:

· Mature manufacturing process

· Moderate cost

· Strong current-carrying capability

· Especially suitable for early-stage products with undefined designs or applications requiring high serviceability

Disadvantages:

· Less aesthetically pleasing

· Low level of assembly automation

· Relatively large size and heavier weight

Have a design ready?

Contact us for a quick quote.

_-_副本.png)