Replacing traditional wiring harnesses in battery packs with FPCBs is a key technological upgrade, enabling battery packs to evolve toward being lighter, more compact, safer, smarter, and easier for mass production.

In the design of power batteries for electric motorcycles, electric bicycles, electric tricycles, and robots, replacing traditional wiring harnesses with FPCBs has become the mainstream trend.

The application of FPCBs is a key technological upgrade that enables battery packs to evolve toward being lighter, smaller, safer, smarter, and more suitable for mass production.

We are committed to being your partner on the journey toward the future. Facing increasingly complex technological challenges and market trends, we leverage our years of experience to explore the possibilities of next-generation products with you, transforming disruptive ideas into market-leading, practical solutions.

With over a decade of experience in the FPCB field, leveraging mature manufacturing processes and profound technical expertise, we are committed to providing customers with high-precision, highly reliable flexible PCB solutions, offering strong support for your product innovation.

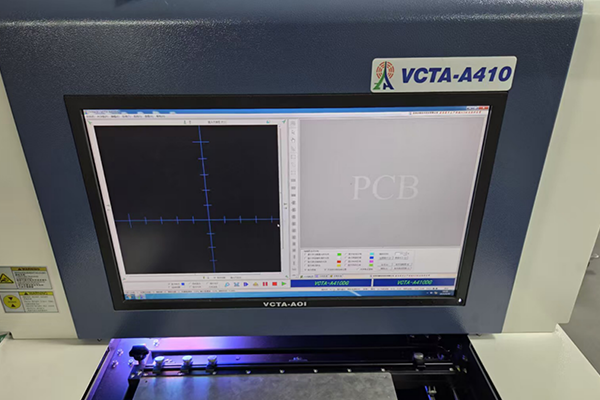

Quality is the lifeline of a company. We are equipped with high-precision inspection equipment such as AOI and 3D measurement systems. From incoming raw materials to final shipment, we carry out more than 20 rigorous inspection processes to ensure that every FPCB performs consistently and reliably in terms of impedance control, bend resistance, and overall dependability, providing customers with zero-defect quality assurance.

We build a comprehensive supply chain system to ensure timely delivery and strict inventory control, continuously improve internal governance, and actively advance digitalization. With our outstanding capabilities, we confidently meet the high demands of the market.

Excellent Management, Accelerating Efficiency for Your Projects

From conceptual sketches to precision finished products, we master every detail of FPCBs. Leveraging our expertise in material selection, circuit design, and process optimization, we can quickly respond to engineering validation, small-batch pilot production, and large-scale mass production. We don’t just provide a circuit board—we deliver core support for the unique requirements of your products.

Have a design ready?

Contact us for a quick quote.

_-_副本.png)